| Production – ETHYLENE VAPORIZER EA 414 |

|

| Realization: 2024 (ZA2300356) | |

| Vyrobeno dle: PED 2014/68/EU, ČSN 690010 | |

| Material: | P355NL1, P420QH, P215NL, P280QH, 42CrMo5-6, Dynagraph |

| Diameter: | 2 068 mm |

| Lenght: | 8 270 mm |

| Weight: | 24 660 kg |

eng

ORLEN Unipetrol RPA s.r.o.

| Production – Cooler 2. St GB 201 –2 pcs: EA204A, EA204B |

|

| Realization: 2024 (ZA2300226) | |

| Made according to: PED 2014/68/EU, ČSN 690010 | |

| Material: | P265GH, 1.4462, P280GH, P305GH, P245GH, 42CrMo5-6, Dynagraph |

| Dimensions 1 piece | |

| Diameter: | 1 892 mm |

| Lenght: | 8 880 mm |

| Weight: | 21 995 kg |

| Total weight – 2 pcs: | 43 990 kg |

ORLEN Unipetrol RPA s.r.o.

IG SERVICE s.r.o.

P & P Industries AG

Teplarna Otrokovice, a.s

|

|

| Realization: 2021 (OP2000027) | |

| RETORT – DESIGN, PRODUCTION AND ASSEMBLY | |

| Material: | W.Nr. 1.4845 |

| Lenght: | 10 000 mm |

| Width: | 3 100 mm |

| Hight: | 2 100 mm |

| Weight: | 6 000 kg |

Unit for thermochemical conversion of solid fuels and secondary raw materials into gaseous and liquid fuels, usable in existing boiler houses. Coal can be fed into the retort and the result will be gas (coal gas), oil (coal tar) and solid residue (semi-coke).

LIBERTY Ostrava, a.s.

ZVU Engineering a.s.

| Production and complete assembly of technology – adiabatic nitration unit – 120 kt/year |

|

| Realization: 2020-2021 (ZA2100156) | |

| Destination: BorsodChem MCHZ s.r.o. Ostrava |

Manufacture and Assembly of 20 apparatuses and exchangers, of which 5 columns

| Material: | 1.4404, 1.4539, P265GH |

| Lenght: | Length up to 27 650 mm |

| Weight: | Up to 22 365 kg/pc |

INTECHA spol. s r.o.

ZVU Engineering, a.s.

HALL – 3

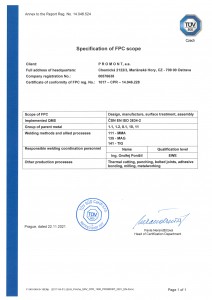

Certification – EN 1090-2 (EXC 4)

The company P R O M O N T, a.s. has successfully carried out a certification audit of the production control system in accordance with Annex V. paragraph 1.3. EP and R Regulation (EU) No. 305/2011 – (TÜV SÜD Czech s.r.o.).

The company P R O M O N T, a.s. received a CERTIFICATE OF CONFORMITY OF PRODUCTION CONTROL according to EN 1090-1 + A1: 2011 issued on 22.11.2021 by TÜV SÜD Czech s.r.o.

The quality system assessment was performed for the type of products: Design and manufacture of steel construction parts, components, kits and structures execution class to EXC 4 according to EN 1090-2.

Lenzing BIOCEL Paskov a.s.

ZVU Engineering, a.s.

ZVU Engineering, a.s.

CASALE SA (Switzerland)

| Destination: Ghubakha, RUSSIA |

|

| REALIZATION: 2018 – 2019 (ZA1700645) | |

| Production of segments for 6 tanks. | |

| The technical requiremments: | ASME Code Sec. II + V + IX ED. 2017, API 650 VIII |

| Material: | SA-516 Gr.60, SA-350 Gr.LF2 Cl1, SA-479 TP316L, SA240GR 304/304L, SA-403 WP304/304L, SA-182 F304/304L, SA 516 Gr.60, SS Gr. 304L, Gr. 316L |

| Dimensions: | Tank height: 5 500 – 12 000 mm, Diameter: 4 500 – 12 000 mm, |

| Thickness of the material: | 5 – 50 mm |

| Weight: | 7 500 – 75 000 kg |

Chemoprojekt, a.s.

| Destination: Basrah, South Refineries Company, IRÁK |

|

| Realization: 2017 (ZA1700371) | |

| Production and installation of PRESSURE VESSELS (2 pcs) | |

| Realization 1: | Production in the area of Shipyard Chvaletice. |

| Volume: | 315 m3 |

| Material: | SA 516 GR. 70 |

| Dimensions: | ID 5 000 x 18 mm, L t.l. = 15 000 mm, |

| Operating pressure: | 1,2 kg/cm2 (1,18 bar) |

| Weight: | 50 000 kg |

| Realization 2: | Production in Ostrava. Oversized transport to Hamburg (Germany). |

| Volume: | 105 m3 |

| Material: | SA 516 GR. 70 |

| Dimensions: | ID 3 000 x 15 mm, L t.l. = 10 000 mm, |

| Operating pressure: | 3,5 kg/cm2 (3,43 bar) |

| Weight: | 22 300 kg |

Stickstoffwerke Piesteritz GmbH

| Destination: Stickstoffwerke Piesteritz GmbH – GERMANY |

|

| Manufacturing of 8 parts of Column for Nitric Acid. | |

| Manufacturing standard: | AD 2000 |

| Material: | W.Nr. 1.4361 – Antinit A610 (Böhler) |

| Dimensions: | a) 4 pcs – 2 200 x 1 100 x 1 100 mm, |

| b) 4 pcs – 950 x 1 050 x 1050 mm, | |

| Weight: | 830 kg/pc and 160 kg/pc |

ŠKODA JS a.s.

MONTIS BAU s.r.o.

CHEMOPROJEKT, a.s.

GEA Wiegand GmbH

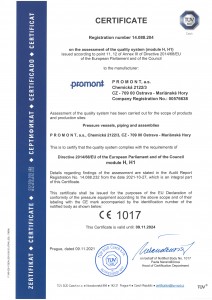

Certification – according to Directive 2014/68 / EU – module H, H1

Certification – according to Directive 2014/68 / EU of the European Parliament and of the Council – module H, H1

On October 5, 2021, the company P R O M O N T, a.s. passed a successful certification audit of TÜV SÜD Czech s.r.o.

Certificate on the assessment of the quality system (module H, H1) issued acdordingto point 11, 12 of Annex III of Directive 2014/68/EU of the European Paliament and of the Council.

Assessment of the quality system has been carried out for products and production sites: Pressure vessels, piping and assemblies

Certificate validity: until November 9, 2024

CHEMOPROJECT NITROGEN, a.s.

| Destination: Sweden (YARA AB Köping) |

|

| Production and supply of pipeline routes (GAS DUCT). 24 ROUTES | |

| Materiál: | W.Nr. 1.4306, W.Nr. 1.4541, P355NL1 |

| Hmotnost: | 102 697 kg |

| Rok výroby: | 2016 – 2017 |

The project was completelly managed by company PROMONT, a.s., e.g. the preparation of drawing documentation based on datasheets, manufacturing, testing, surface tretament, vendor documentation and preparation for expedition.

CHEMOPROJECT NITROGEN, a.s.

BIOCEL Paskov, a.s.

CHEMOPROJECT NITROGEN, a.s.

CHEMOPROJECT NITROGEN, a.s.

Core-Tech AS (AMOF FJELL, Norsk Energi) / Elkem

Development Challenge III-a

The company P R O M O N T, a.s. implements EU Grant project within the Operational programme Business and Innovations in project No. 2.2 RV03/1980

Intensification and increase of competitive advantage of production high-pressure tube exchangers – P R O M O N T, a.s.

Acquired technologies:

- Table type horizontal boring machine CNC: 4 000 x 2 500 x 1 500 mm

- 4 rolls hydraulic bending machine: 35 mm

- Inverter welding machines (4 pc.)

- Horizontal turning machine: 4 000 mm

- Plate shear hydraulic: 3 100 / 10 mm

- Vertical knee-type milling machine: 1000 x 300 x 420 mm

- Radial boring machine